Huatai can provide turnkey projects with an annual output of 5,000 to 20,000 tons of threonine. The threonine extraction equipment from wheat starch produced by Huatai has the characteristics of easy raw materials, simple process, reasonable price, and customized functions.

Threonine is an important nutritional supplement that can be used to fortify cereals, pastries, and dairy products. Like tryptophan, it can relieve fatigue and promote growth and development. In medicine, due to the hydroxyl group in its structure, threonine has a hydrating effect on human skin. When combined with oligosaccharide chains, it plays an important role in protecting cell membranes. It also promotes phospholipid synthesis and fatty acid oxidation in the body. Its preparations have medicinal properties that promote growth and combat fatty liver disease, and it is a component of complex amino acid infusions. Threonine is also a raw material for the production of monobactam, a highly effective, hypoallergenic antibiotic.

Threonine is used in medicine, chemical reagents, food fortifiers, and feed additives. Its use as a feed additive is particularly rapidly increasing. It is often added to the feed of young piglets and poultry, where it is the second limiting amino acid in pig feed and the third limiting amino acid in poultry feed.

With the improvement of people’s living standards and the development of the livestock industry, threonine is widely used as a feed amino acid in piglet feed, breeding pig feed, broiler feed, shrimp feed, and eel feed. It has the following characteristics:

(1) It can adjust the balance of amino acids in feed and promote growth;

(2) It can improve meat quality;

(3) It can improve the nutritional value of feed raw materials with low amino acid digestibility;

(4) It can produce low-protein feed, which helps to save protein resources;

(5) It can reduce the cost of feed raw materials;

(6) It can reduce the nitrogen content in livestock and poultry feces and urine, and the ammonia concentration and release rate in livestock and poultry houses.

The extraction of threonine is a delicate and systematic process, the core of which is to efficiently separate threonine from wheat starch slurry.

First, the starch slurry is subjected to an acid hydrolysis step, using an acidic environment to decompose protein and release threonine.

Then, sodium hydroxide is used for neutralization to adjust the pH value to an appropriate range. The concentration step further increases the concentration of threonine, creating conditions for subsequent purification. In the alcohol extraction stage, threonine is separated from a complex mixture by using the specific solubility of ethanol.

Solvent recovery not only reduces costs, but also reflects the concept of environmental protection. Finally, through the crystallization step, a high-purity threonine product is obtained.

In terms of equipment selection, reactors, neutralization pots, concentrators, extraction tanks, evaporators and crystallization tanks are required to ensure the smooth progress of the entire extraction process.

In addition, the optimization of process conditions, such as reaction temperature, time, pH value and solvent selection, are crucial to extraction efficiency and product quality.

The storage of threonine should also be noted. It should be placed in a dry, cool and ventilated place to avoid direct sunlight to maintain its quality.

Threonine production mainly adopts fermentation method, using genetically engineered bacteria (such as Escherichia coli, Corynebacterium glutamicum mutants) to convert carbon sources, nitrogen sources, etc. into threonine. The fermentation process requires precise control of metabolic pathways to increase production.

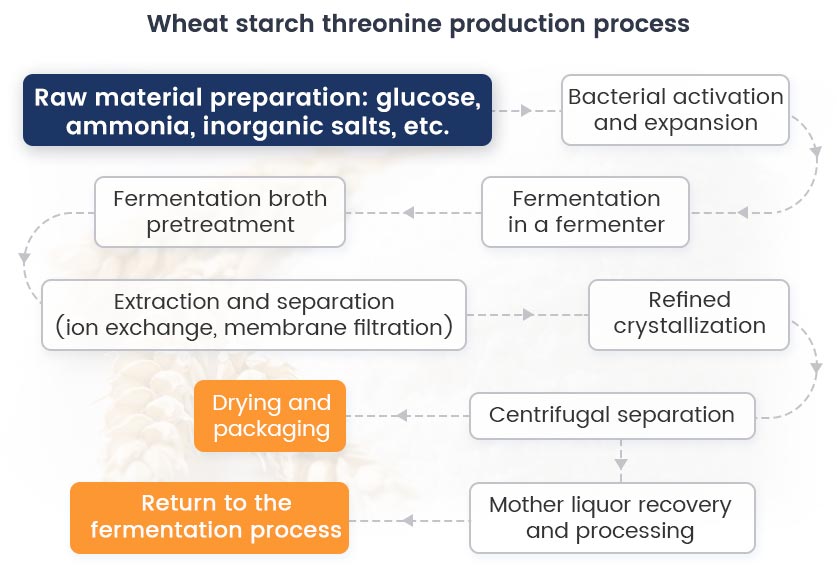

Process flow chart for producing threonine from wheat starch:

Process flow chart for producing threonine from wheat starch

1. Raw material preparation

– Carbon source (protein): mainly glucose (or starch hydrolyzed sugar), with a concentration controlled at 250-300g/L;

– Nitrogen source (glutamic acid): ammonia water or ammonium sulfate, providing nitrogen elements required for fermentation;

– Inorganic salts: adding potassium dihydrogen phosphate, magnesium sulfate, etc., to supplement the nutrients required for microbial growth.

2. Activation and expansion of strains

– Strains: Genetically engineered Corynebacterium glutamicum or Escherichia coli are used as production strains;

– Activation: inoculate the preserved strains into the slant culture medium and culture at 30-32℃ for 18-24 hours;

– Expansion culture: transfer to the seed tank step by step, through the shake bottle, small seed tank to the large seed tank, and finally connect to the fermentation tank.

3. Fermentation in a fermenter

– Fermentation conditions:

– Temperature: 32-35℃;

– pH: 6.5-7.5 (regulated by adding ammonia water);

– Dissolved oxygen: maintain dissolved oxygen concentration ≥ 30% saturation;

– Fermentation cycle: 48-60 hours.

– Process control: real-time monitoring of bacterial concentration, substrate consumption and threonine accumulation, and adjustment of feeding strategy.

4. Fermentation broth pretreatment

– Heating and sterilization: 80-90℃ for 10-15 minutes to inactivate bacteria;

– Filtration and impurity removal: remove bacterial residues, proteins and other impurities through a plate and frame filter press or a disc centrifuge to obtain a clarified fermentation broth.

5. Extraction and separation

– Ion exchange: Utilize the amphoteric property of threonine to adsorb threonine through a strong acidic cation exchange resin, and then elute with ammonia water;

– Membrane filtration: Use nanofiltration or reverse osmosis membrane to remove small molecular impurities and salts, and concentrate the threonine solution to a concentration of 15-20%.

6. Refined crystallization

– Acid adjustment crystallization: Add hydrochloric acid to the concentrated solution to adjust the pH to the isoelectric point of threonine (pH=5.6), cool to 10-15℃ for crystallization;

– Recrystallization: If the purity is insufficient, dissolve the crystals and decolorize with activated carbon, and then crystallize again for purification.

7. Centrifugal separation and drying

– Centrifugation: Separate crystals from mother liquor by horizontal spiral centrifuge, and reduce the moisture content of wet crystals to 15-20%;

– Drying: Use airflow drying or fluidized bed drying, and control the temperature at 60-70℃ to make the moisture content ≤0.5%;

– Packaging: After screening, pack according to specifications, and the purity of the finished product is ≥98.5%.

8. Mother liquor recovery

– The mother liquor after centrifugation contains residual threonine and nutrients, which is returned to the fermentation process after membrane filtration and concentration to improve the utilization rate of raw materials.

Modern threonine fermentation technology has achieved continuous production with a single tank volume of more than 500m³ and an annual output of 45,000 tons through strain improvement and process optimization. The raw material conversion rate (glucose→threonine) reaches 45%-50%, which is a typical representative of the industrial production of amino acids.

Henan Huatai Grain and Oil Machinery Co., Ltd. has specialized in the manufacturing of starch and grain processing equipment for over 37 years. With a 100,000-square-meter modern production facility, equipped with advanced equipment such as laser cutting machines, fully automatic welding robots, and CNC precision machining centers, we produce over 200 large-scale grain processing lines annually.

Huatai Workshop

Huatai Oil Machinery is a leading manufacturer and supplier of starch processing equipment in China. We offer affordable equipment and cost-effective starch production processes. We have implemented numerous starch processing plant projects worldwide and provide customized production solutions. We welcome inquiries from customers.

If you want to build a wheat starch threonine plant, the conditions are relatively high, because to build a wheat starch threonine plant, you need to meet the following hard conditions: 1. High capital requirements, 2. There is a government-approved land that meets the requirements, 3. There is a stable supply and sales market for raw materials (wheat or other crops with high starch content).

Based on our many years of experience in the industry, we can provide you with a tailor-made wheat starch threonine plant solution based on the production capacity, land area and funds of your starch plant.

Therefore, please provide us with detailed information about your request to facilitate our communication and provide you with a more detailed quotation:

1) Is the starch raw material you want to process wheat? If you want to process other raw materials, please provide other raw material types;

2) The tonnage of wheat or other starch material that needs to be processed every day; (This is very important to us. We will customize different process drawings and equipment lists for you according to your production requirements.)

We hope you can provide as detailed information as possible so that we can provide you with equipment quotation, flow chart, equipment configuration list and other services. Thank you.