Huatai can provide turnkey projects with an annual output of 5,000 to 20,000 tons of glucose. The glucose extraction equipment from wheat starch produced by Huatai has the characteristics of easy raw materials, simple process, reasonable price, and customized functions.

Glucose (English: glucose) is a monosaccharide with a chemical formula of C6H12O6. It is widely found in natural foods such as grapes and figs. As the core energy source of organisms, it is converted into ATP through metabolic reactions (such as glycolysis) to directly support life activities. Pure glucose is a colorless crystal with a lower sweetness than sucrose. It is easily soluble in water and mainly maintains blood sugar balance in the human body.

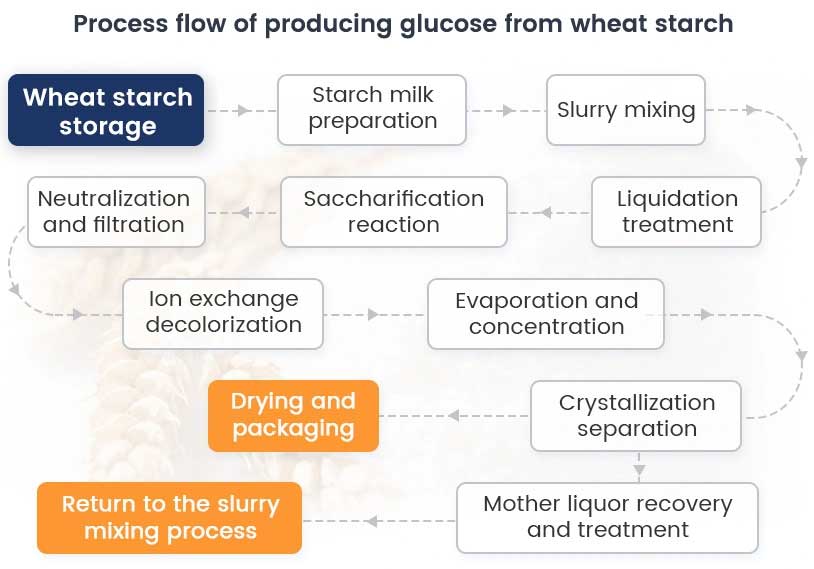

The following figure shows the process flow of Huatai’s 700 tons/day wheat starch production of glucose

Process flow of producing glucose from 700tpd wheat starch

Detailed description of the process flow

1. Preparation of starch milk

– Transport wheat starch from the storage bin to the mixing tank, add appropriate amount of clean water, stir evenly to make starch milk with a concentration of about 30%-35%, control the temperature at 30-35℃, and the pH value at 6.0-6.5.

2. Slurry adjustment

– Add appropriate amount of α-amylase and calcium chloride (as enzyme activator) to the starch milk, adjust the pH value to 6.0-6.5, and control the temperature at 85-90℃ to make the starch milk reach the appropriate reaction conditions.

3. Liquefaction treatment

– Transport the adjusted starch milk to the liquefaction tank through a pipeline, pass steam and quickly heat it to 95-105℃, keep it for 1-2 hours, so that α-amylase can work and decompose starch macromolecules into short-chain dextrins and oligosaccharides.

– The liquefaction end point is judged by iodine solution color development. When the solution does not show blue when it encounters iodine, it indicates that liquefaction is complete.

4. Saccharification reaction

– Cool the liquefied liquid to 60℃, adjust the pH value to 4.5-5.0, add saccharifying enzyme (β-glucosidase), react at 60-62℃ for 12-24 hours, and decompose dextrin and oligosaccharides into glucose.

5. Neutralization and filtration

– After saccharification, add sodium carbonate or sodium hydroxide to neutralize to pH 6.0-6.5 to terminate the activity of the enzyme.

– Remove insoluble impurities (such as protein, fiber, etc.) through a plate and frame filter press or a vacuum drum filter to obtain a clear glucose solution.

6. Ion exchange decolorization

– The filtered glucose solution passes through a cation exchange resin and anion exchange resin column in turn to remove metal ions and pigments.

– Then pass through an activated carbon decolorization column to further adsorb pigments to achieve a higher transparency of the solution.

7. Evaporation and concentration

– The decolorized glucose solution is sent to a vacuum evaporator, evaporated and concentrated at 60-70℃ and vacuum degree 0.08-0.09MPa to increase the glucose concentration to 70%-75%.

8. Crystallization separation

– The concentrated solution is cooled to 40-45℃, seed crystals are added to induce crystallization, and then slowly cooled to 20-25℃ to allow glucose crystals to precipitate.

– Crystals and mother liquor are separated by centrifuge or filtration equipment to obtain wet glucose crystals.

9. Drying and packaging

– The wet crystals are dried by air flow drying or fluidized bed drying at 60-70℃ to a moisture content of ≤0.5%.

– The dried glucose crystals are screened and graded, and packaged into finished products according to specifications.

10. Mother liquor recovery and treatment

– The separated mother liquor contains residual glucose, which is returned to the pulping process for reuse to improve the utilization rate of raw materials.

Through the above process, wheat starch can be efficiently converted into glucose, which is suitable for food, medicine, chemical industry and other fields. In actual production, the equipment scale and process parameters can be adjusted according to demand.

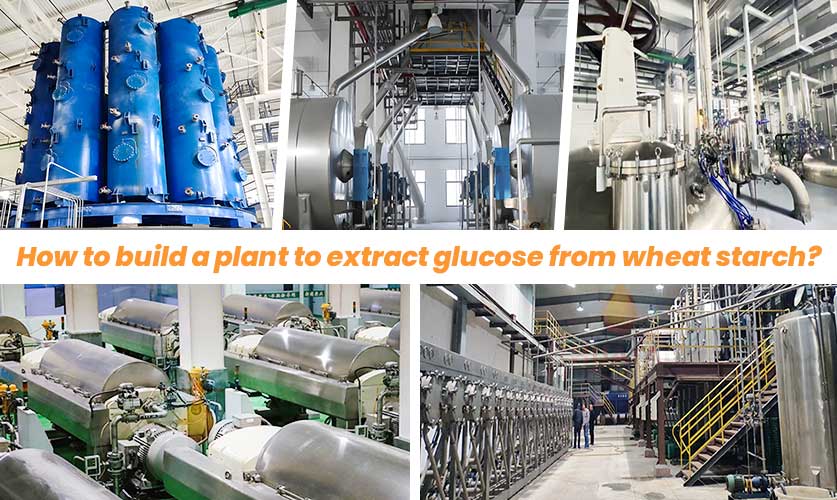

Actual shot of the wheat starch glucose production workshop

Wheat starch glucose extraction equipment

Henan Huatai Grain and Oil Machinery Co., Ltd. has specialized in the manufacturing of starch and grain processing equipment for over 37 years. With a 100,000-square-meter modern production facility, equipped with advanced equipment such as laser cutting machines, fully automatic welding robots, and CNC precision machining centers, we produce over 200 large-scale grain processing lines annually.

Huatai Workshop

Huatai Oil Machinery is a leading manufacturer and supplier of starch processing equipment in China. We offer affordable equipment and cost-effective starch production processes. We have implemented numerous starch processing plant projects worldwide and provide customized production solutions. We welcome inquiries from customers.

Building a wheat starch to glucose plant requires several key requirements: 1. High capital requirements; 2. Government-approved land that meets the requirements; and 3. A stable supply and market for raw materials.

Based on our years of experience, we can provide you with a customized wheat starch to glucose plant solution based on your starch plant’s production capacity, land area, and funding.

Please provide us with detailed information about your request so we can facilitate communication and provide you with a more detailed quote:

1) Is the starch raw material you wish to process wheat? If you wish to process other raw materials, please provide the type of raw material;

2) The daily tonnage of wheat or other starch you wish to process; (This is very important to us; we will customize the process drawings and equipment list based on your production capacity.)

We appreciate your detailed information so we can provide you with equipment quotes, flow charts, equipment configuration lists, and other services. Thank you.