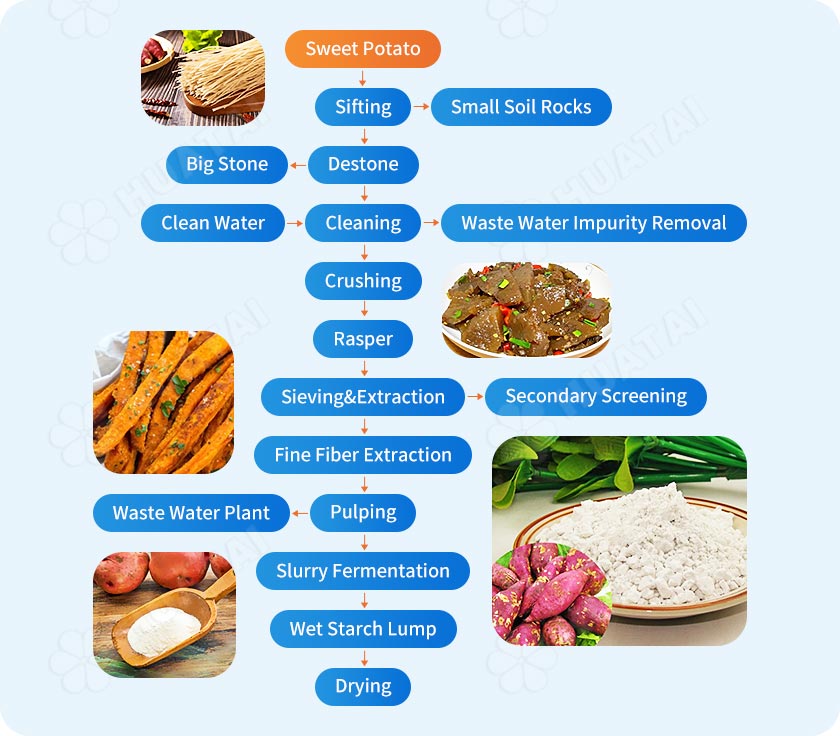

The sweet potatoes starch process flow is as follows: raw material pretreatment – soaking – crushing and grinding – screening – launder separation – alkali and acid treatment and cleaning – centrifugal separation and drying. Its production process is as follows:

After fresh sweet potatoes are harvested, they are usually cut into slices or shreds and dried in the sun or fire to make dried sweet potatoes. This dried sweet potato is inevitably mixed with various impurities during processing and transportation, so it must be pretreated.

There are two types of pretreatment: dry method and wet method. The dry method uses screening equipment and air separation equipment. Wet processing is done using a washing machine or a washing bucket.

To increase the starch yield, alkaline water soaking can be used. Generally, saturated lime milk or 1% dilute alkali solution is added to the soaking water to make the pH value 10-11. The soaking time is about 12 hours, and the temperature is controlled at 35-40 degrees Celsius. After soaking, the water content of sweet potato slices is 60%.

The soaked sweet potato slices enter the hammer crusher with water for crushing until they reach a certain fineness, and are discharged out of the machine through the sieve holes.

The temperature of the dried potatoes rises instantaneously during the crushing process, and part of the starch is easily gelatinized by heat, which affects the separation of starch and potato residue during sieving. It is not easy to settle during separation in the launder, resulting in an increase in secondary flour and affecting the production of good flour out rate.

To prevent the starch from gelatinizing easily during one crushing process, a two-pass crushing and separate screening process can be adopted. That is, the dried potatoes are crushed in the first step and sieved, and then crushed in the second step and sieved again.

During the crushing process, to reduce the instantaneous temperature rise, the slurry concentration is adjusted according to the different crushing particle sizes in each pass. The first pass is 3-3.5 Baume degrees, and the second pass is 2-2.5 Baume degrees.

At the same time, a homogenizer is used to control the amount of dried sweet potatoes, balance the slurry, avoid overloading the crusher, and also facilitate the separation of the launder.

The sweet potato paste obtained after the dried sweet potatoes are crushed is also called the feed liquid. It must be screened to separate the residue, which is the fiber. Usually, a flat shaking screen is used.

The material liquid enters the screen surface and is required to be screened evenly and continuously sprayed with water. The starch passes through the screen holes with water and enters the slurry storage tank, while the slag remains on the screen surface and is discharged from the screen tail.

The screen cloth is 120 mesh nylon cloth. During the sieving process, the feed liquid contains pectin and other viscous substances that remain on the screen surface, which affects the separation effect of the screen. Therefore, the screen cloth should be washed frequently to ensure that the screen holes are unobstructed.

After fine screening, the starch is generally separated into proteins using a flow trough. Its advantages are that it is easy to construct, uses less steel, saves kinetic energy, and is more stable in operation. The disadvantages are large land occupation, intermittent operation, low separation efficiency, large starch loss, and poor working conditions.

To further improve the purity of starch, the starch must be treated with alkali and acid during the cleaning process. Starch alkali, acid treatment, and cleaning are all carried out in a cement tank with a stirring device. The size of the cement tank is determined according to the production capacity, and the mixer speed is about 60 rpm.

The starch milk coming from the launder is first treated with alkali to remove impurities such as alkali-soluble protein and pectin in the starch.

The method of alkali treatment is to slowly add 1 degree of Baume dilute alkali solution into the starch emulsion, control the pH value to 12, start the stirrer at the same time, and mix thoroughly. After half an hour, stop stirring until the starch has completely precipitated. , drain the upper waste liquid, and inject clean water twice to make it close to neutral.

During the alkali treatment process, sodium chlorate solution with a concentration of 35 degrees Baume can also be added, and the dosage shall not exceed 0.4% of the dry base starch weight.

Because sodium hypochlorite is a strong oxidant, it has strong bleaching and sterilizing effects, so it can achieve the purpose of whitening and antisepsis. After being treated with alkali, sodium hypochlorite and washed, the

starch is then treated with acid. Its purpose is to dissolve acid-soluble proteins, neutralize the alkalinity remaining during alkali treatment, and also inhibit the activity and reproduction of microorganisms. Industrial hydrochloric acid can be used for acid treatment. During operation, it must be added slowly and stirred thoroughly to control the pH value of the starch milk to about 3. Prevent local over-acidity, causing starch loss. The acidified starch milk is treated with alkali in the same way to precipitate the starch, remove the upper waste liquid, add water to wash, and finally make the starch slightly acidic with a pH value of about 6 to facilitate the storage and transportation of starch.

The starch obtained after cleaning has a high moisture content and must be dehydrated by a centrifuge to reduce the starch moisture content to less than 45%. Some factories deliver or use it directly as wet starch. In order to facilitate storage and transportation, the dehydrated wet starch needs to be dried to reach the required starch moisture content. Usually the moisture content of sweet potato starch is 12%-13%. Air flow drying can be used for starch drying because it has the advantages of fast drying speed, high efficiency, high equipment production capacity and low equipment cost.