The crushing process is one of the main processes in the production of potato starch. The crushing of potato pieces belongs to wet crushing.

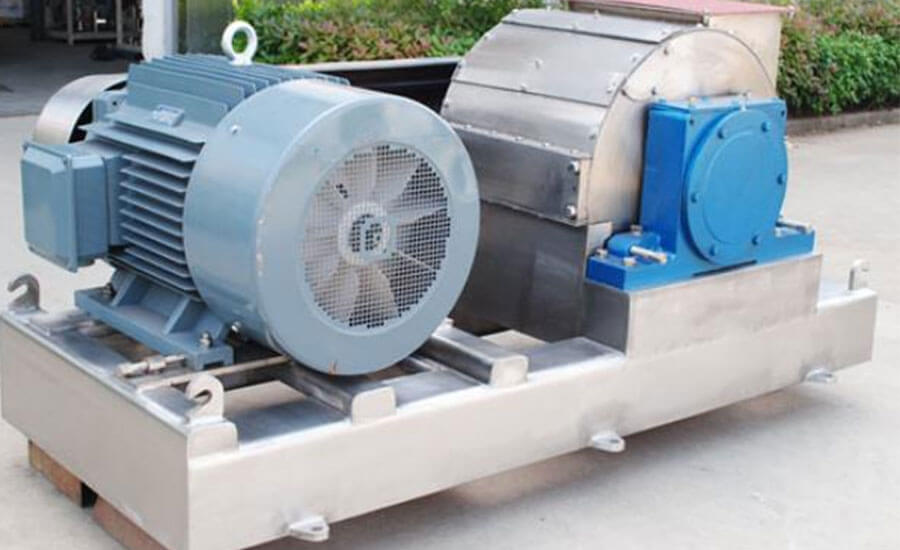

The sweet potato crusher consists of a frame, an upper and lower body, a rotor, a hammer, and a transmission system. The lower body is connected to the frame as a whole and is firmly connected to the reinforced concrete foundation with anchor bolts.

Rubber vibration-damping pads should be placed at the connection. The lower body is equipped with a screen, the upper body is welded with a tooth plate around the circle, and there is a water spray pipe on the top.

After the potato pieces enter the crusher from the feed port, they are repeatedly struck and collided by the high-speed rotating hammers and fixed tooth plates. The materials between the screen and the hammers are subjected to strong friction.

Under the action of these repeated strikes, collisions, and frictions, the potato pieces are physically broken and starch particles are released from them, which fall into the slurry pool through the screen.

Huatai sweet potato crusher has improved some structures, such as increasing the weight of the hammer, increasing the diameter of the rotor, and reducing the main shaft speed, which greatly reduces the vibration of the machine body.

Although the speed is reduced, the circumferential linear velocity does not change much due to the increase in the diameter of the rotor.

A flywheel is added to the end of the shaft, and the moment of inertia of the hammer is increased, which reduces the power, improves the work efficiency, and greatly improves the stability of the dynamic rotation.