Starch Sugar Solutions

Huatai has advanced starch sugar equipment production technology, can provide you with medium and large starch sugar production equipment, and can undertake the general contract construction of starch sugar projects. At the same time, we can also sell related products, such as starch sugar production lines, glucose syrup/maltose Pulp production line, crystalline glucose production line, high fructose syrup production line, maltodextrin production line, etc.

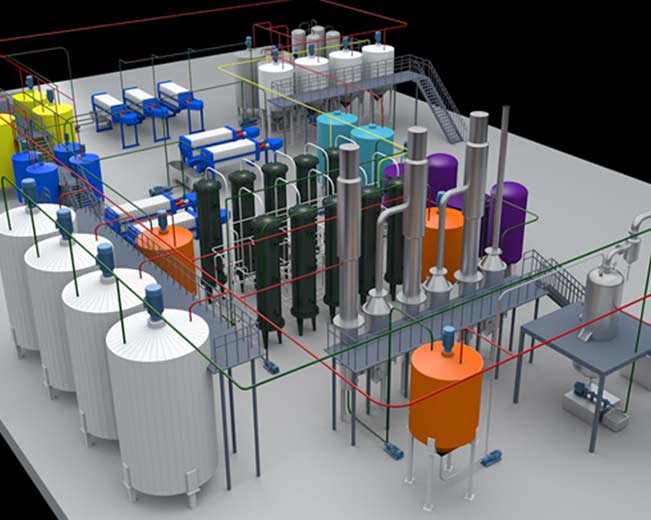

Main process and equipment

Huatai’s experienced professional process design and R&D team, with sophisticated equipment manufacturing and excellent automation control team, tailor-made starch sugar production lines with high degree of automation, energy saving and environmental protection, and advanced technology, mainly including online automatic pulping, liquefaction Heat energy recovery, automatic decolorization, automatic simulated continuous separation, automatic chromatographic separation and MVR or TVR multi-effect evaporation systems.

Using the advanced double-enzyme production process, the starch is liquefied, saccharified, filtered, decolorized, and separated to obtain qualified sugar solution, and then the sugar solution is evaporated by multi-effect falling film to reach the required concentration. The production line adopts advanced intelligent control system, which can adjust PH online and add enzyme preparation accurately. The off-cycle evaporation system can realize one-key start and stop. The integrated design of liquefaction and evaporation can make full use of the heat source used in liquefaction flash evaporation and reduce steam consumption.

Main equipment: fixed bed separation system, simulated continuous separation system, multi-effect waste heat evaporation system

The process mainly includes starch milk sizing, liquefaction, saccharification, filtration, decolorization, separation, evaporation, cooling crystallization, centrifugal separation and air drying systems. The syrup cooling and crystallization adopts a fully automatic continuous crystallization system, the crystal is well formed and the product quality is stable.

Main equipment: fixed bed separation system, simulated continuous separation system, multi-effect waste heat evaporation system, air drying

The production process of high fructose syrup mainly includes starch milk mixing, liquefaction, saccharification, coarse filtration, fine filtration, separation, evaporation, isomerization, chromatographic separation, mixed bed separation and deodorization. The production line is fully intelligently controlled, which can adjust PH online and add enzyme preparations accurately. The chromatographic system adopts the latest generation of chromatographic separation technology, simulated sequential moving bed (SSMB), with stable control, good separation effect and low water consumption. The separation system adopts advanced simulated continuous separation process, which effectively reduces water consumption and acid-base consumption.

Main equipment: full bed separation system, simulated continuous separation system, isomerization system, chromatographic separation system, multi-effect waste heat evaporation system

The production process mainly includes starch milk sizing, liquefaction, saccharification, protein filtration, decolorization, separation, evaporation and spray drying systems. Myander provides you with maltodextrin engineering solutions of all sizes, experienced technicians provide first-class process and mechanical design, tailor-made for your plant, and provide a turnkey package of services, equipped with advanced The automatic control system ensures the automatic and smooth operation of the entire production line.

Main equipment: fixed bed separation system, simulated continuous separation system, multi-effect waste heat evaporation system

Huatai advantage

Huatai Group can undertake medium and large starch sugar production lines, and can design, develop, produce and install a full set of medium and large starch sugar production lines by itself. We can provide you with a complete set of turnkey projects ranging from process design, equipment layout, civil engineering planning and design, automation control, equipment manufacturing, installation and commissioning to personnel training and after-sales service. As a powerful factory, Huatai has a strong technical team, production and installation team to solve all kinds of problems in the construction and production process for you.