The role of the slurry cleaning machine in starch equipment is mainly reflected in its efficient cleaning ability and contribution to the starch production process.

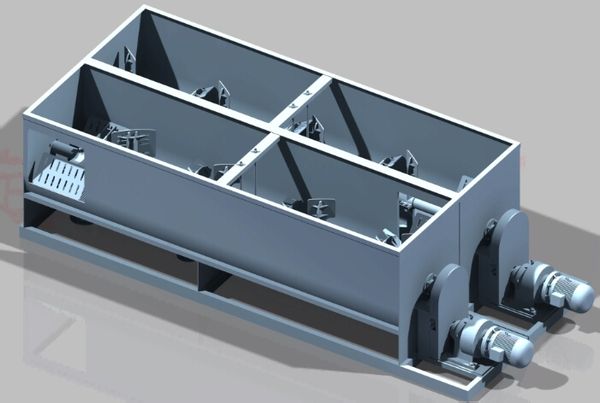

The slurry cleaning machine adopts the principle of counter-current washing. Through the propelling action of the rotating blades, the raw materials and the water in the cleaning tank form a reverse movement. This design enables the friction between the blades and the material to effectively remove sediment attached to the surface of the raw material. After soaking and specific gravity settling, impurities will float away with the flow of water or sink into the water collection tank, thus achieving efficient cleaning of raw materials. This cleaning method has the advantages of stable moving speed, reduced raw material damage rate, high cleaning degree, large capacity, and low water consumption. It is very suitable for material cleaning in complete production lines such as potato starch and cassava flour. Blade cleaning machines are often used in conjunction with dry screening to further ensure the purity and efficiency of starch production.

In addition, the application of blade cleaning machines in starch production is also reflected in its efficient use of water resources. By using circulating water and three-stage sedimentation filtration technology, the rinsed water can be reused after treatment, which not only reduces the consumption of fresh water, but also improves the utilization rate of water resources, helping to reduce production costs and reduce environmental pollution.

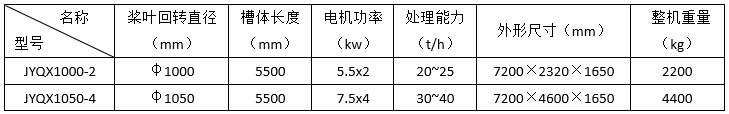

Technical Data

In summary, the role of the pulp cleaning machine in starch equipment is to ensure the purity and efficiency of starch production through its efficient cleaning capacity and rational use of water resources, while reducing production costs and environmental impact. , is an important piece of equipment on the starch production line.