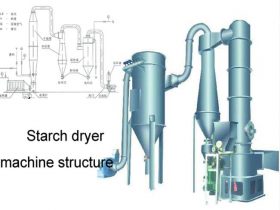

Airflow dryer (airflow drying system)

Brief intro:

Equipment function: The air drying system is widely used for drying powder, and the humidity is controlled between 14%-20%. Application: sweet potato starch, cassava starch, potato starch, wheat starch, corn starch, pea starch and other starch production enterprises. Features: 1. …

Equipment function: The air drying system is widely used for drying powder, and the humidity is controlled between 14%-20%.

Application: sweet potato starch, cassava starch, potato starch, wheat starch, corn starch, pea starch and other starch production enterprises.

Features:

1. The airflow drying system fully considers various factors, such as airflow turbulent motion, cyclone separation and heat exchange, and the process configuration and technical parameters of each part have a strong theoretical basis.

2. In terms of products production, computer control is adopted in all production links such as 3D simulation analysis of equipment and material cutting, which greatly improves product quality and production accuracy.

3. The whole system adopts automatic control, through the prediction of feed moisture or inlet and outlet air temperature.

4. Automatically adjust the feed volume and air intake volume of the entire drying system to ensure the moisture stability of the product.

Working principle:

The cold air enters the radiator sheet through the air filter, and the heated hot air enters the drying air duct. At the same time, the dried wet material enters the hopper of the feeding unit from the wet starch inlet, and is transported into the elevator through the feeding auger. The elevator rotates at a high speed and throws the wet material into the drying air duct, so that the wet material is suspended in the high-speed hot air flow and conducts heat exchange. After the material is dried, it enters the cyclone separator with the air flow, and the separated dry material is discharged through the closed-air auger, and the finished product is screened and packed into the warehouse; and the separated exhaust gas is pumped into the exhaust air duct by the exhaust fan and sent to the atmosphere.

Get in touch with us!