Different tapioca flour processing methods require different machines:

1. Dry processing of tapioca flour

This processing method can be briefly summarized as cleaning, slicing, and grinding. The required machines are: dry sieve, paddle washing machine, peeling machine, slicer, hammer crusher. Henan Jinrui will recommend tapioca flour processing machines of different specifications for you according to your needs.

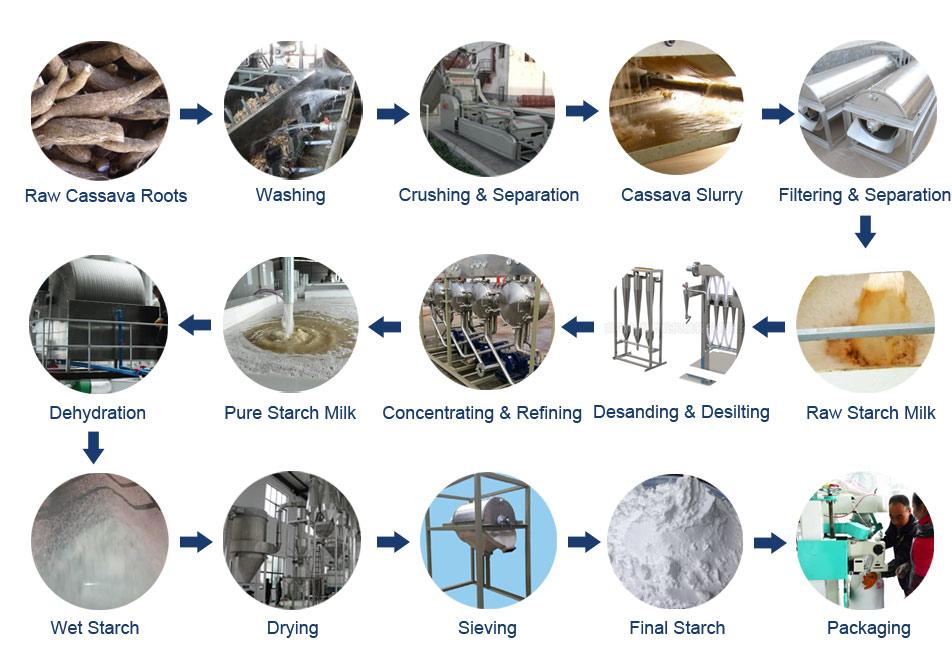

2. Wet processing of tapioca flour

Wet processing is currently the most efficient method of tapioca flour production on the market. First, clean and wash cassava by dry sieve and paddle washer, then peel cassava by peeling machine, cut and grind cassava by cutter and rasper machine, dewater cassava pulp by plate-frame filter machine, mill cassava cake by hammer crusher, finally dry and sieve tapioca flour by flash dryer and sifter sieve. In the operation of these tapioca flour processing machines, the time from the input of fresh cassava raw material to the output of final tapioca flour is very short, which can ensure that the final flour is not affected by any impurities. Thus you can get high quality tapioca flour.

Henan Huatai supply cassava starch making machine, cassava starch production line, any need please email to info01@starchproduction.com