Corn: Moisture % (m/m) ≤ 14% Impurity rate % ≤ 2% Starch content ( m/m ) ≥ 70%

Starch: 65-68% germ, 6-8% fiber powder, 8-10% protein powder, 4.5-6%

1 ton of corn can produce 0.3-0.32 tons of alcohol, and 1 ton of washing powder can produce 1.15 tons of maltose syrup.

The traditional corn wet grinding method is adopted (i.e. countercurrent soaking of corn with sulfurous acid aqueous solution to extract soluble components to obtain corn soaking water, crushing by tooth grinding, cyclone separation and extraction of corn buds, screening and residue removal, disc separator and cyclone separator) Corn starch is produced using a combination of separate chamber protein removal and closed-circuit cycle production processes.

This ensures the reliability of the process. At the same time, the process water is fully utilized to achieve the purpose of saving water.

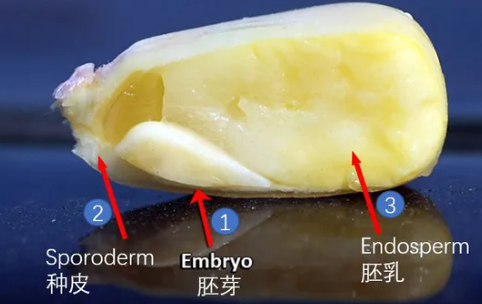

Corn starch is made from corn as raw material. After raw grain cleaning, soaking, crushing, fine grinding, separation, starch refinement, dehydration, drying, metering and packaging, the finished product is obtained. During the production process, germ, fiber powder, corn gluten meal and corn liquor are simultaneously separated. These by-products must be separated, washed, dehydrated, dried and measured and packaged respectively. Finally complete the entire production process. The corn starch production line is a set of continuous flow operations. Corn steep liquor can also be mixed with corn fiber powder to make gunite fiber, which is a good raw material for making feed.

Henan Huatai supply modified starch processing, any need please email to info01@cnoilmachine.com