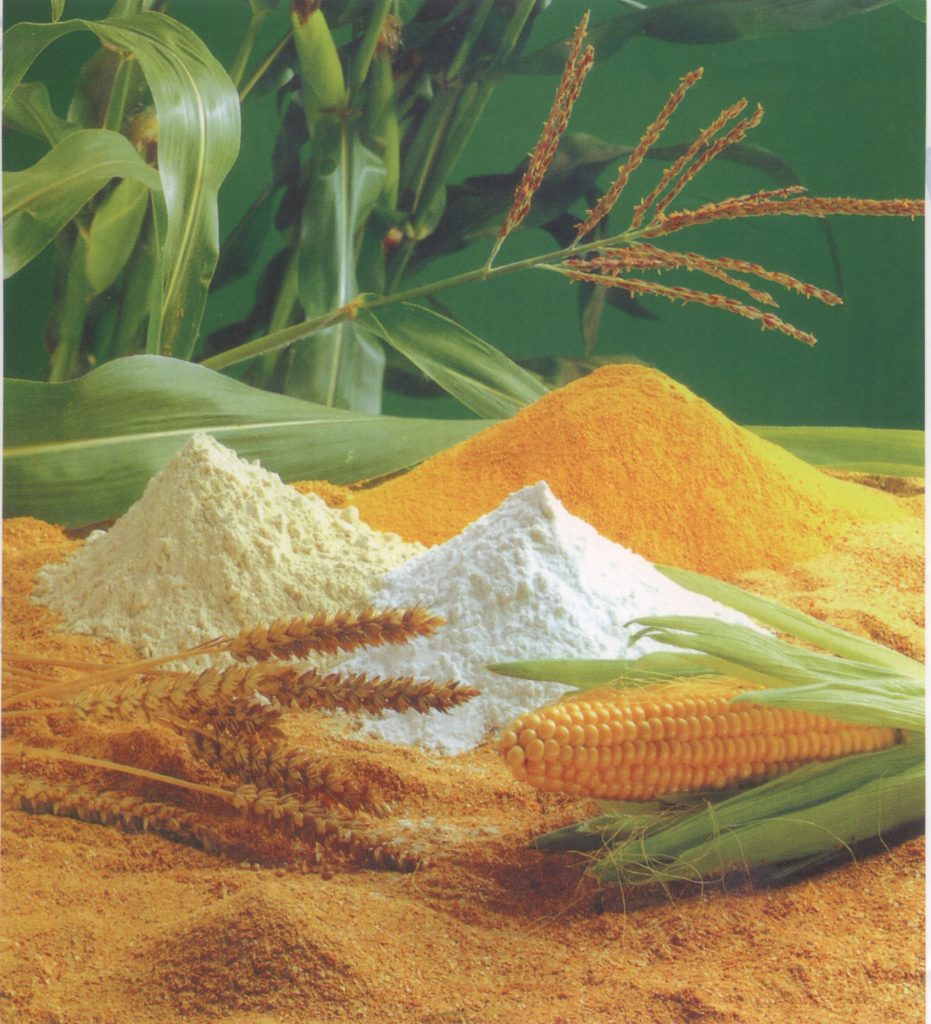

Corn Starch Production process

Corn cleaning: Purchased corn often contains impurities, such as soil, stones, straw, etc. First, these impurities are removed through screening, winnowing, magnetic separation and other equipment to ensure the purity of the corn and provide a good raw material basis for subsequent processing. For example, the vibrating screen can separate large impurities in corn through screens of different apertures; the air separation equipment uses wind power to blow light impurities such as dust and shriveled kernels away from the corn.

Soaking: Soak the cleaned corn in an aqueous solution containing sulfurous acid. The soaking time is generally 30 – 40 hours. Sulfurous acid can soften corn kernels, destroy the cell structure of corn, make it easier to separate starch from other components such as protein, and inhibit the growth of microorganisms. During the soaking process, the corn absorbs water and expands in volume to facilitate subsequent crushing operations.

Crushing and separation: The soaked corn passes through crushing equipment, such as a hammer crusher, to break the corn into small pieces to initially separate the germ, endosperm and husk in the corn kernels. Then through the germ separation tank, the density difference is used to make the germ float on the water and separate from other parts. The germ is rich in oil and can be further processed to extract corn oil.

Grinding and screening: Grind the material after removing the germ, and grind the endosperm to release starch granules from the cells. Commonly used grinding equipment includes disc refiners, etc. The ground slurry is screened through screens of different specifications to separate impurities such as fiber and obtain purer starch milk.

Protein separation: Starch milk still contains a certain amount of protein. Through centrifugal separation, the protein and starch density differences are used to separate the protein. A high-speed centrifuge can make the starch milk separate under the action of centrifugal force. The heavier starch particles will precipitate at the bottom of the centrifuge, while the lighter proteins and other substances will remain in the upper layer.

Washing and dehydration: The starch milk after protein separation also contains some soluble impurities and needs to be washed multiple times to further improve the purity of the starch. The washed starch is dehydrated through equipment such as a vacuum drum filter or a plate and frame filter press to reduce the water content of the starch to a certain level to form wet starch.

Drying and packaging: Wet starch has a high moisture content, which is not conducive to storage and transportation. It needs to be dried through air dryers, tube bundle dryers and other equipment to reduce the moisture content of starch to about 13%. The dried corn starch is screened, measured, and packaged before being sold on the market as a finished product.

Huatai supply large and small corn starch processing machine, corn milling, corn deep processing machinery, any need please email to info01@starchproduction.com