Cassava starch is mainly used as raw material in industrial sectors such as food, sugar, medicine, feed, textile, paper making, and chemical industries.

The cassava starch production process is a physical separation process, which is to separate the starch in the cassava raw material from other substances such as cellulose, white, and inorganic substances.Processing cassava into starch requires following steps: unload cassava, remove impurities, cleaning, crushing, starch screening, sand removal, concentration and separation,dehydration, drying, sifting, package.

When purchasing raw materials, sampling inspection should be carried out in accordance with cassava standards. The cassava is weighed by a weighbridge and stored in the stockyard, and then loaded using forklifts.

The cassava in the factory yard is sent to the silo with a forklift, and fed into the belt conveyor through the feeding device, and then enters the dry cleaning screen to screen and clean the stones, soil and other impurities in the cassava. After entering the paddle cleaning machine, the cassava is thoroughly cleaned and also plays the role of peeling.

The washed cassava is transported to the cassava chopper for chopping, and the cassava pieces are sent to the rasp grinder, where they are filed into a very fine slurry.

The coarse starch slurry from the crusher is transported to the screening unit. The screening unit is integrated and includes four conical centrifugal screens, slag pumps, and slurry pumps. When the crude pulp is screened through the three-stage extraction screen, it is washed by the process water from the cyclone recovery unit in a counter-current manner, thereby maximizing the separation of starch.

The starch milk temporarily stored in the rough slurry tank is pumped into the desander to remove sand and soil that may remain in the starch slurry.

The crude starch milk after passing through the rotating filter enters the disc separator to separate the fine residue (or enters the first-level concentration cyclone group). The cell liquid separated from the top flow of the separator enters the sewage treatment station as wastewater, while the bottom flow The separated starch milk enters the starch milk tank for temporary storage, and then is transported to the cyclone group through a pump for refining and washing.

The clearer slurry (with starch content ≤0.3g/L) separated in the first stage of the cyclone group is transported to the common pipe of the centrifugal screen group as process water for washing starch. The starch is recovered and washed, and the fiber fines are separated.

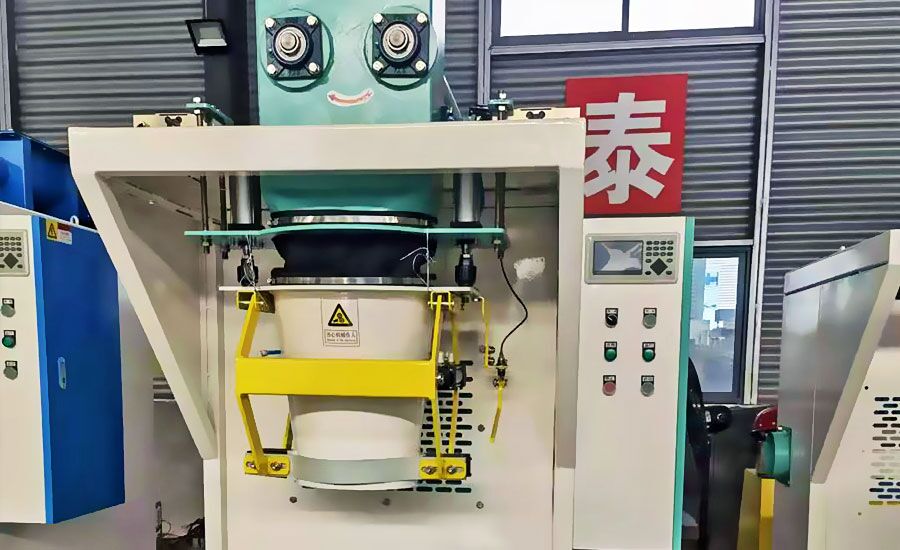

The refined starch milk is transported to the siphon scraper centrifuge, which dehydrates the starch milk to wet starch with a water content of about 35%, and then sends it to the drying section.

The wet starch with a water content of 38-40% first enters the buffer box of the drying unit, and then enters the elevator through the speed-adjustable feeding auger. The high-speed rotating elevator impeller sends the wet starch into the drying air duct and mixes it with the filtered and heated air. During the drying process, through computer comprehensive control of the inlet air temperature and feed speed, the product moisture is automatically controlled within the required range. The starch separated from the shakron is discharged through the air-closed air-closed device and then enters the conveying auger, and then is sent to the starch screen.

The dried starch needs to be further screened to remove possible impurities and reach the fineness of the corresponding national standards.

The packaging of the product can be in different forms according to the needs of the user, such as the size of the packaging bag, etc., generally 25kg/bag.

The finished products are continuously transported by the belt conveyor into the finished product warehouse.

The standard cassava starch production scale is generally: 6TPH, 10TPH, 12TPH, 20 TPH, 25TPH, 35TPH, 50TPH, 75TPH and 100TPH. Henan Huatai also supply customized cassava starch solution according to detail needs.

Well, maybe you have the following questions, how much does a starch plant cost? How to build a turnkey starch production plant? We will answer your doubts in two parts.

First, building a starch production plant requires considerable resource investment and many aspects need to be considered. The main process is as follows: preliminary communication, making requirements, our factory technicians propose design plans, come to our factory for inspection, sign contracts, equipment production, delivery, overseas installation, equipment operator training, trial operation and formal production.

In this process, you need to consider the following practical issues.

1) Are you building a factory for the first time, or are you expanding? For example, if you previously owned a starch processing plant, you want to expand the production scale and build another production line for market reasons.

2) Do you have a stable supply of related materials? For example, you have land for growing cassava, sweet potatoes, or potatoes, or other grains, or you have signed a cooperative procurement agreement with local farmers. You can provide us with the raw material capacity you need to process and how many tons you need to process per day, and we will design a complete production line for you based on your production capacity.

3) Do you have the qualifications to build a factory, do you have land that meets the requirements for starch processing plant construction and sufficient funds to build a factory?

Through comprehensive consideration of these three aspects, you can consider whether you meet the conditions for establishing a starch production plant.

Second, if you think you really need to purchase equipment or build a factory, please provide the following information. Based on these situations, we will provide you with the most suitable solution for you, including starch flow chart and equipment configuration list. If it is a general contracting project, we will provide you with detailed quotations for civil engineering, steel structure, personnel training, etc. after later communication. Therefore, please provide the following information in the form below so that we can provide you with a detailed quotation, such as:

1) Your starch processing technology requirements: starch production, grinding or deep processing, or other processes;

2) Starch plant materials and capacity: For example, how many tons of cassava do you want to process per day?

3) In which country is your project located? Can you leave your company name?

4) Other special funding and land requirements, such as adjusting the process flow according to funding conditions, adjusting the process flow according to topography and environment, etc.?

The more detailed the information, the more efficient we can serve you.

In addition, please note that you should not leave only meaningless numbers or words, or topics that are irrelevant to our business. Our sales manager will classify such inquiries as spam and will not respond. Thank you.